Achieve Superior Results with Industrial Milling Media Solutions

35+

Years of business

2000+

Customers Served

75+

Countries across the World

Small is Huge!

For over four decades, FOX Industries has been driving remarkable changes and technological advances worldwide. Our commitment to innovation fuels breakthroughs across all industries. FOX Grinding Media, including steel balls, ceramic beads, and glass beads for ball mills, supports advancements in particle size reduction and transformative nano-level technologies. Additionally, FOX steel finishing and tumbling media are designed to enhance the metal finishing process and deliver superior results. Join us in shaping the future with FOX’s comprehensive range of industrial steel and ceramic milling media solutions—the key to unlocking nanoparticles and revolutionizing industries.

Isn’t it time you had Industrial Milling Media you can count on?

Grinding Media

Our products include high-performance steel milling media for superior durability, ceramic milling media for optimal wear resistance, and versatile glass milling media designed for smooth, efficient grinding.

Tumbling Media

Polishing, Deburring, Cleaning or Finishing metal parts? Need Metal Finishing and Deburring Media for your Vibratory Tumbler? Which tumbling media will get your burnishing job done?

Precision Grinding Media & Materials

Zirconium Silicate Beads

Zirconium silicate beads are high-quality grinding media ideal for use in ball mills for various milling and grinding applications. These ceramic beads offer high hardness, durability, and chemical inertness, ensuring efficient particle size reduction and uniform dispersion in ball mills. Commonly used in industries like paint, ink, and mineral processing, zirconium silicate beads provide consistent performance and low wear rates, making them a cost-effective choice for achieving fine, uniform particle sizes in ball mill processes. Their reliability and efficiency make them a top choice for optimizing ball mill operations.

| Description | Properties |

|---|---|

| Shape | Spherical |

| Composition | Zirconium and Silicate |

| Color | White |

| Specific Density | >3.7 gr/cm3 (kg/dm3) |

| Bulk Density | >2.5 gr/cm3 (kg/dm3) |

| Hardness | 1050 Hardness (Hv) |

Click Here To Get Pricing, Technical Data And RecommendationsHelp is a click away!

×

Ceria Stabilized Zirconia Beads

FOX ceria beads (ceria stabilized zirconia beads) are highly beneficial for use in ball mills. Ceria beads are known for their high density and hardness, making them ideal for grinding applications. The high density of FOX ceria beads allows for enhanced milling efficiency, as they impart greater impact force on the materials being processed, resulting in finer particle sizes and shorter processing times. Ceria beads are a cost-effective and efficient choice of ceramic milling media for particle size reduction processes in ball mills.

Yttria Stabilized Zirconia Beads

Unlock unrivaled wear resistance and technical precision with FOX Industries’ yttria beads (yttria stabilized zirconia beads) — the pinnacle of ceramic grinding media excellence for ball mills. These yttria beads surpass both ceria beads and zirconium silicate beads in providing superior performance for ball mill applications. Thanks to their superior hardness and wear resistance, yttria beads are the perfect solution for any ball milling process requiring low contamination. Whether you’re using ceramic beads for fine grinding, dispersion, or mechanical alloying, FOX Industries’ yttria beads deliver unmatched efficiency and longevity in critical applications.

Glass Beads

FOX glass beads are precision-engineered, high-quality spherical beads designed for optimal efficiency in ball mills and dispersion processes. Made from durable glass, these beads offer consistent size and shape, ensuring uniform grinding and particle size reduction in various ball mill applications, including pharmaceuticals, paints, coatings, and food products. The smooth surface of FOX glass beads minimizes contamination and wear, making them ideal for both wet and dry ball milling environments. Available in a range of sizes, our glass beads provide superior performance, enhancing productivity and product quality in ball mill operations.

| Description | Properties |

|---|---|

| Shape | Spherical |

| Composition | Glass |

| Color | Clear |

| Sizes | All sizes available |

| Specific Density | 2.5 gr/cm3 (kg/dm3) |

| Bulk Density | 1.5 gr/cm3 (kg/dm3) |

| Hardness | 6 Mohs |

Visit our Glass Spheres page

OR

Click Here To Get Pricing, Technical Data And RecommendationsHelp is a click away!

×

Steel Balls and Grinding Media

FOX steel balls offer superior durability and performance across a wide range of ball milling applications. Specifically designed for ball mills, FOX provides four distinct options to meet diverse needs: Carbon Forged Steel Balls, Carbon Steel Balls, Chrome Steel Balls, and Stainless Steel Balls. Carbon Forged Balls deliver exceptional strength and impact resistance, ideal for heavy-duty ball milling. Carbon Steel Balls are known for their hardness and cost-effectiveness, making them a practical choice for many ball mill processes. Chrome Steel Balls provide excellent wear resistance and precision, making them perfect for high-precision ball milling tasks. Stainless Steel Balls offer outstanding corrosion resistance, suitable for ball mill applications requiring a high degree of purity and hygiene. Each type of steel ball is engineered to ensure optimal efficiency, reduced contamination, and enhanced product quality in ball mill operations.

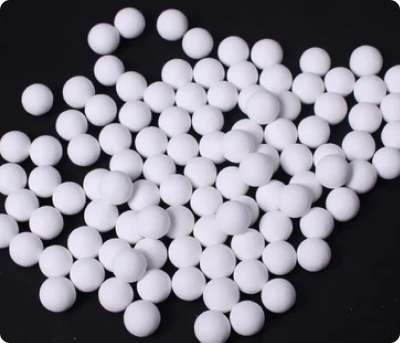

Alumina Balls and Grinding Media

FOX alumina balls and cylinders are a high-performance solution designed for precision ball milling in ball mills. Made from high-purity alumina, FOX alumina balls and cylinders offer exceptional hardness, wear resistance, and chemical inertness, ensuring durability and minimizing contamination in ball mills. Ideal for applications involving ceramics, minerals, and electronic materials, these alumina balls and cylinders enhance grinding efficiency and product quality in ball mill processes. Available in various sizes, FOX alumina balls and cylinders ensure superior particle size reduction and dispersion, making them the perfect choice for optimizing ball mill performance.

| Description | Properties |

|---|---|

| Shape | Spherical, Cylindrical |

| Composition | Alumina Oxide 90% or 95% |

| Color | White |

| Sizes | All sizes available |

| Bulk Density (90% Alumina) | 3.53 gr/cm3 (kg/dm3) |

| Hardness (90% Alumina) | 8 Mohs |

| Bulk Density (95% Alumina) | 3.67 gr/cm3 (kg/dm3) |

| Hardness (95% Alumina) | 8 Mohs |

OR

Click Here To Get Pricing, Technical Data And RecommendationsHelp is a click away!

×

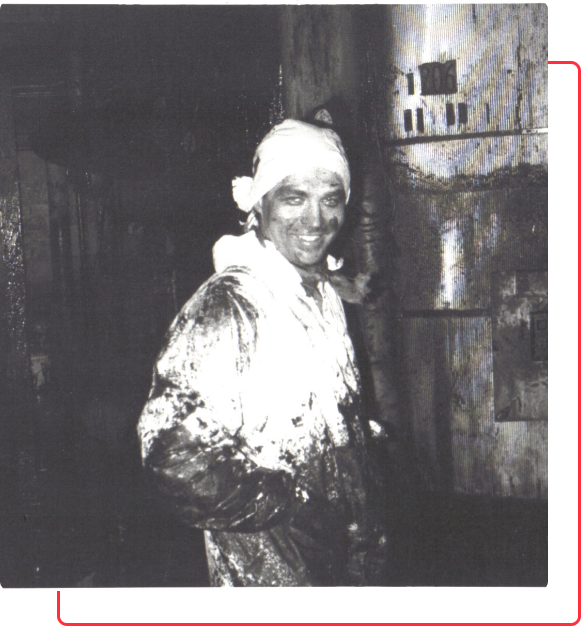

FOX Industries – The Company

Thirty years ago, here’s where you would have found me: At the bottom of an ink tank, deep in printing ink, rebuilding a ball mill. I’d be down inside the mill chamber, spending hours getting my hands dirty.

My name is Charles Richardson, President and CEO of FOX Industries.

I’d often be called in to rebuild, design, and improve drive and mixing assemblies. Time and again, my customers faced the same problem: Production Managers had no control over their milling processes because they were at the mercy of the machines.

Inevitably, the mills would break down, shut down the production line, and bring my customers’ businesses to a screeching halt. That hands-on experience opened my eyes and gave me unique insights into the milling process. One of the things I learned was how fundamental and important grinding media was to the process itself.

That discovery helped me understand the importance of creating quality steel and ceramic milling media that keep your mills, and your business, running smoothly.

Determined to stay head of the curve, and meet the needs of our customers, we invested heavily in the research and development of high-quality steel and ceramic grinding media.

Today, our ongoing research into ultra-fine particle size reduction is changing the world, one bead mill at a time.

If you want a partner who truly understands your needs…Choose FOX.